Choosing the right counter-top material for your needs is an important process of every new construction home, as well as many renovation projects among homeowners.

The decision falls to much more than aesthetic though. Will you be doing a consistent amount of cooking and/or baking? Do you want the ability to cut on the surface? Would you like to place a hot pan directly on the surface without causing damage? Will it stain?

These are among only a few of the common questions contractors will discuss with their customers before advising them on appropriate material choices.

For the average homeowner, the choice typically comes down to two materials: granite or quartz.

However, what many consumers may be unaware of is that Quartz counter-tops aren’t actually one solid slab of stone like their granite counter-tops. They are in fact manufactured.

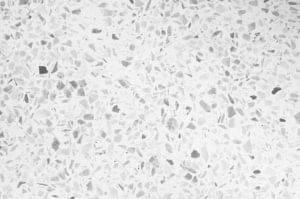

The process of making Quartz counter-tops is actually quite fascinating as well as quite simple, too. Developed 57 years ago by the Breton company in Italy, they began making counter-tops using bits of crumbled quartz and other stones (occasionally pieces of glass, mirrors and metals) mixed with a cement-based or polymeric binder.

This method created a highly sturdy counter-top with a similar look and feel to natural stone.

There are many other interesting properties to Quartz, as well. In fact, its a very environmentally friendly option as no quarrying for the slab is specifically required. Instead, the quartz and other fragments within each slab are mostly waste products from quarrying or recycled materials.

A non-porous material, quartz counter-tops are highly resistant to staining, unlike other choices such as granite or marble. It is also scratch resistant as well as heat-resistant.

The biggest downfalls most commonly associated with quartz at the present time are lack of design options as well as a high price tag. Quartz is typically priced similarly to Granite so it ultimately up to the homeowners personal preference.